AMEX Plating, Incorporated, has been in the metal finishing industry for more than 40 years. With our friendly and experienced staff, we take pride in our reputation for high quality service with the fastest possible turnaround.

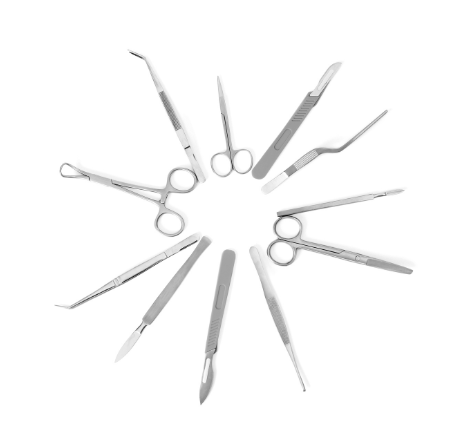

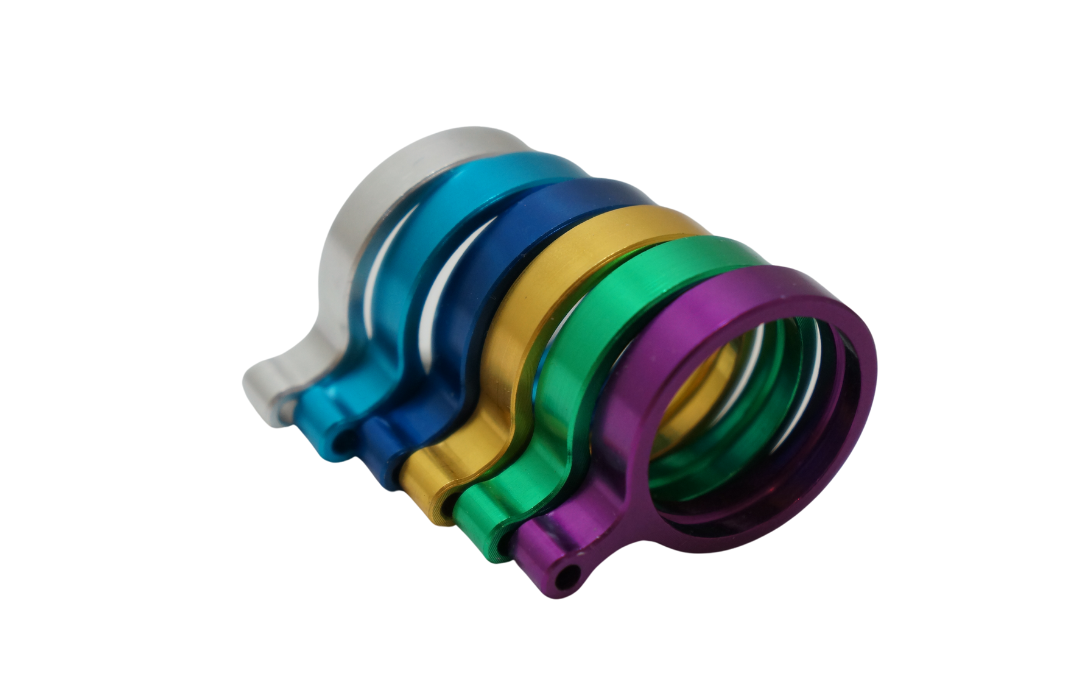

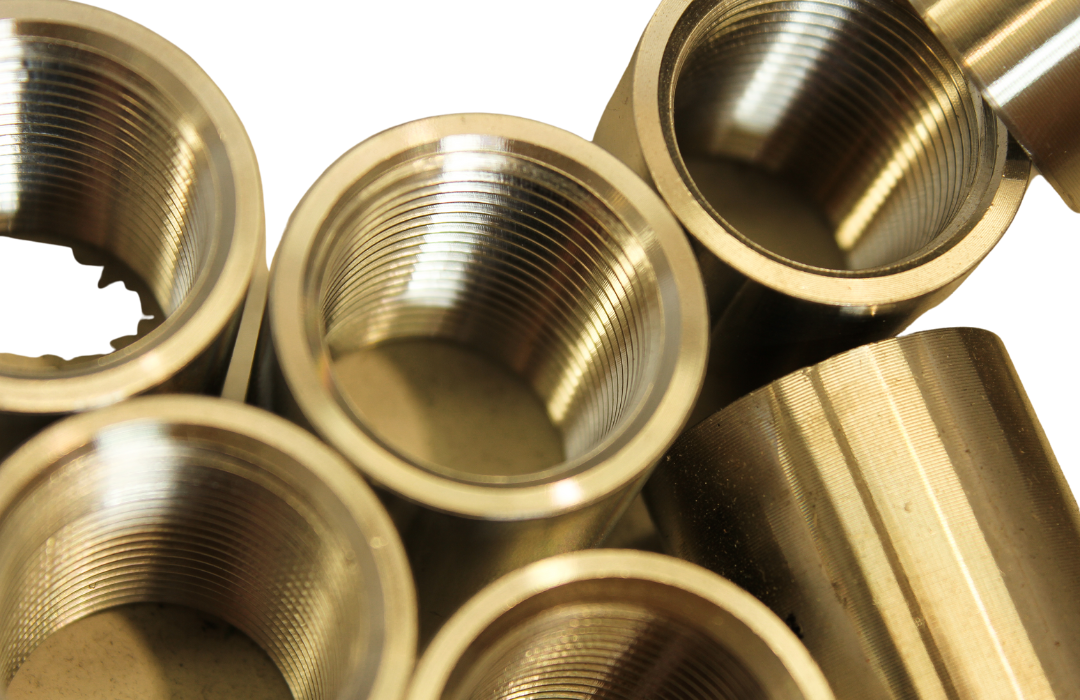

AMEX’s reputation for quality and workmanship, diversity in process offered, and ability to meet rigid specifications has led it to serve a broad base of industries including aerospace, computers, defense, electronics, medical, telecommunications, and robotics.

Our on-site laboratory staff reviews and adjusts solutions daily to ensure all parts are processed to the dimension stipulated. AMEX Plating’s customer service department is equipped to provide fast and efficient service. In addition, we provide free pick-up and delivery around the Bay Area. We also provide many options for shipping nationally.

AMEX Plating contributes its success to a strong group of loyal employees, with more than eighty percent of our team having tenures at AMEX for more than 25 years.